Gazeeka Model 870i Service Guide

Version 2023

Definitions

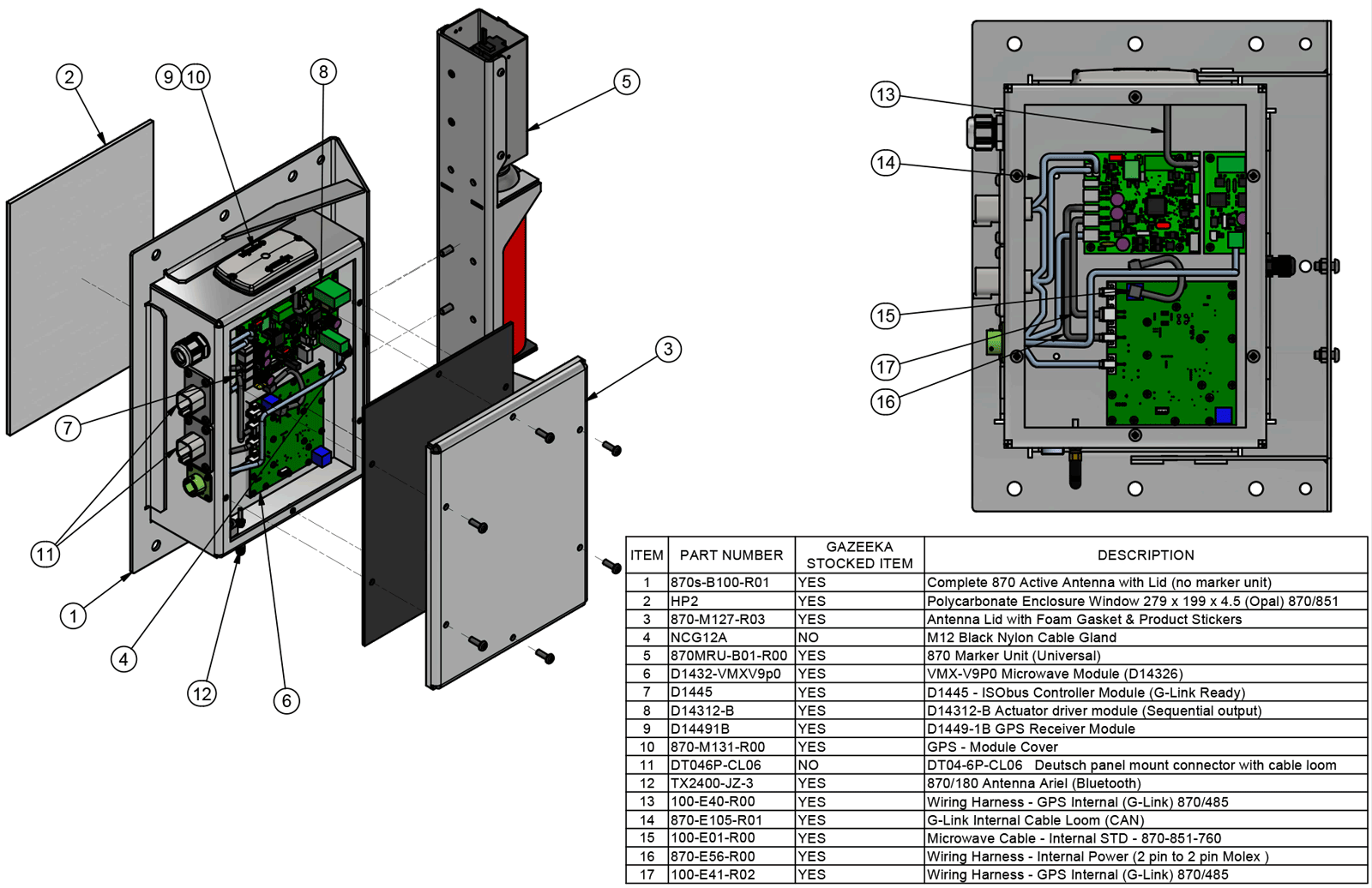

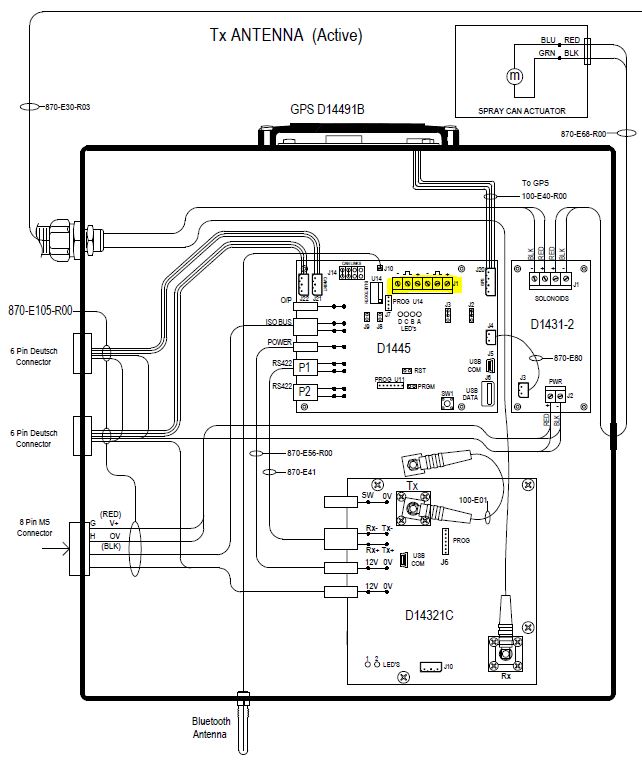

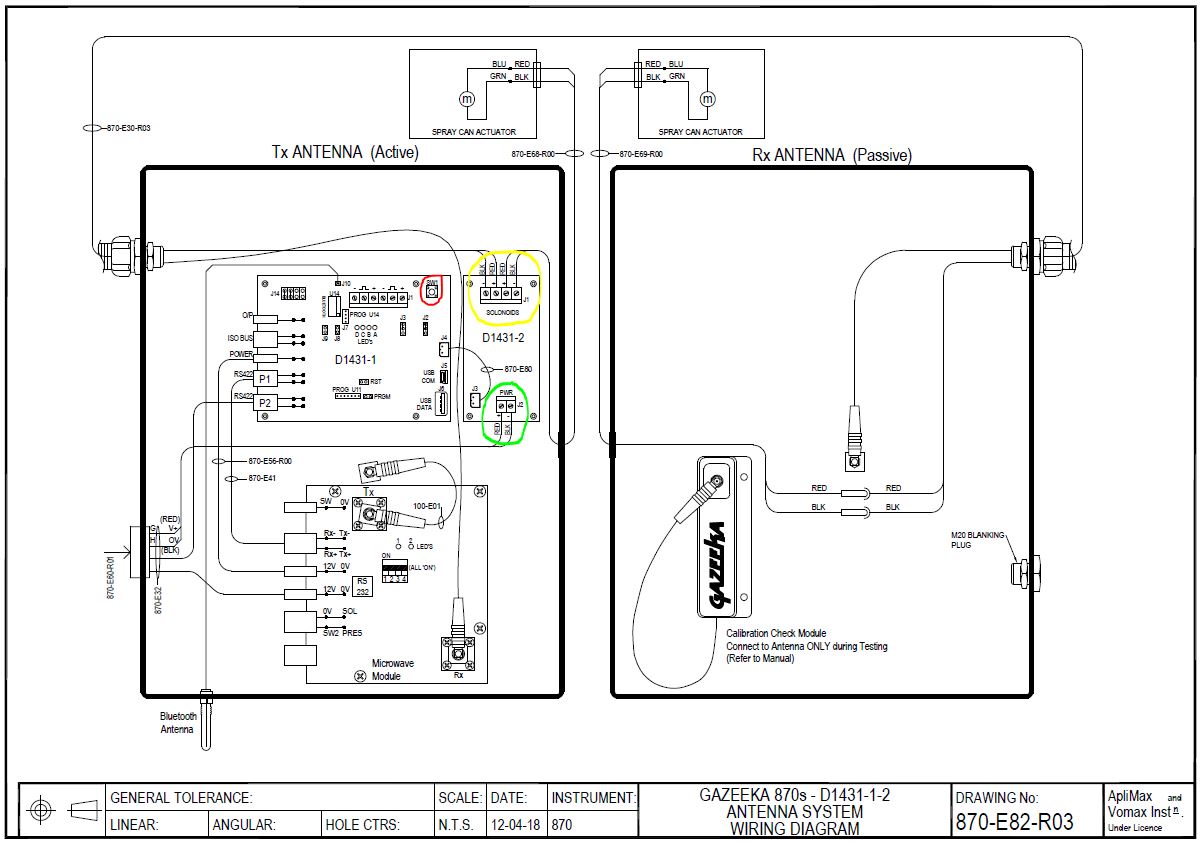

This is the Gazeeka antenna which houses the electronics and is typically always mounted on the left-hand side of the baler behind the bale chamber.

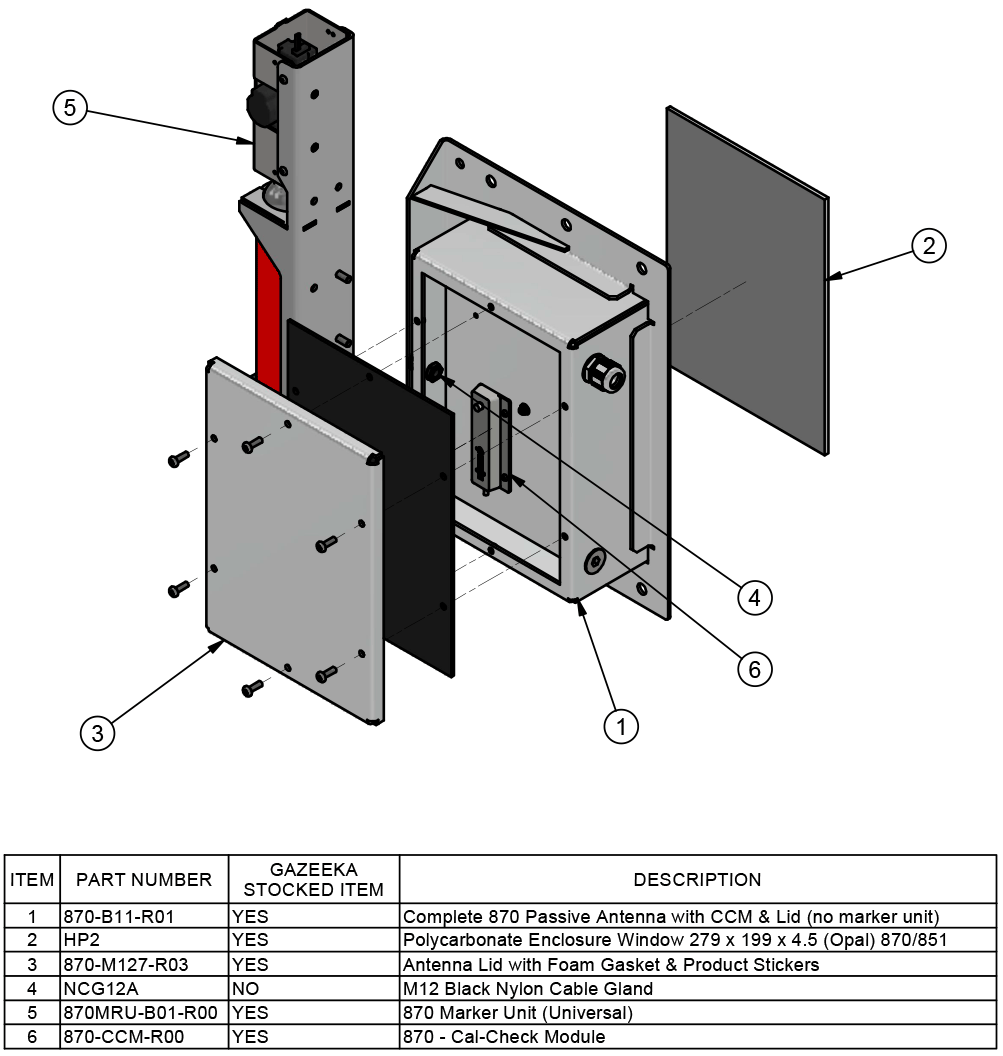

This is the antenna opposite to the Active Antenna and has no electronics in it.

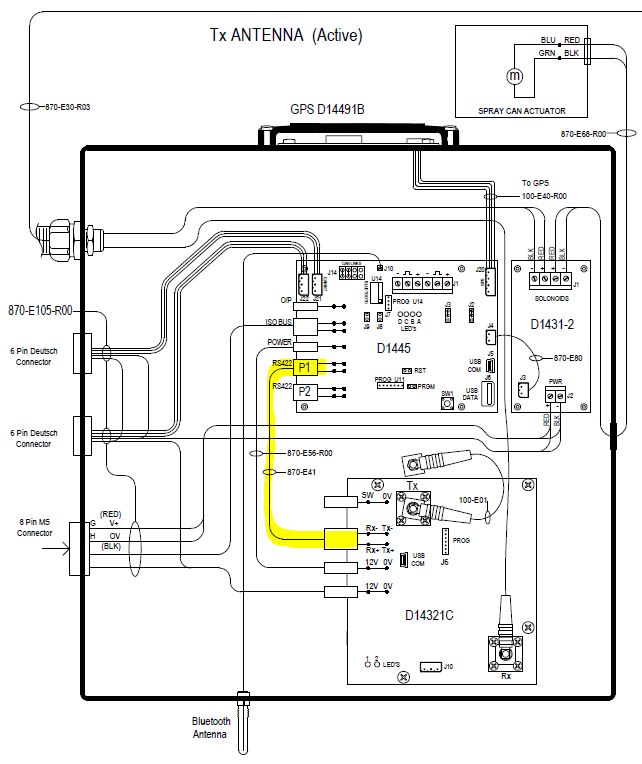

This is the top printed circuit module in the antenna. This module receives the raw microwave values from the Microwave Module and calculates the moisture. This is also the module which does all the communication with the hay baler and terminal in the tractor. There have been a number of versions of this module over the years. The module name is printed on the PCB and may be a D1394, D1400, D1431-1 or D1445.

This is a bottom printed circuit module in the Antenna. This module generates and receives the microwave signals and measures their energy and speed (like a multi-meter measures voltage and current). The microwave values are sent to the Controller Module. There have been a number of versions of this module over the years. The module name is printed on the PCB and may be a v6, v7p2, v8p0 or v9p0.

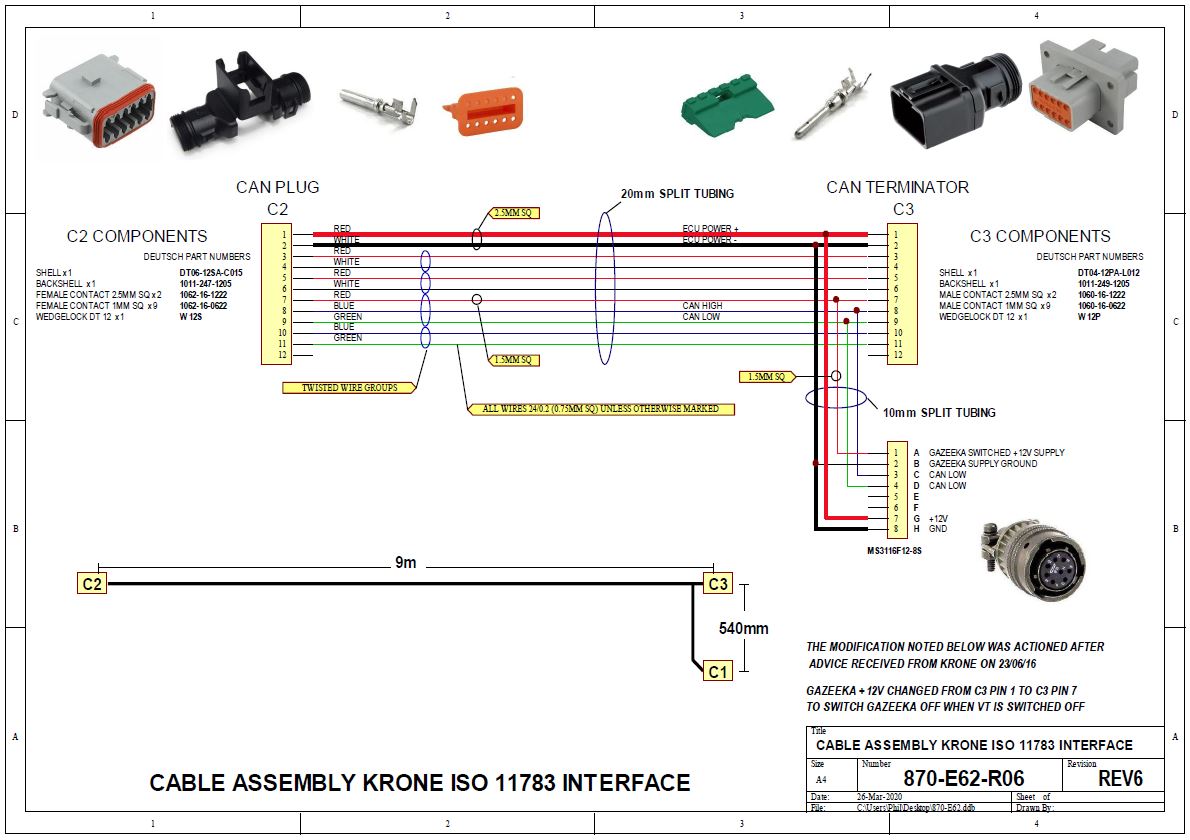

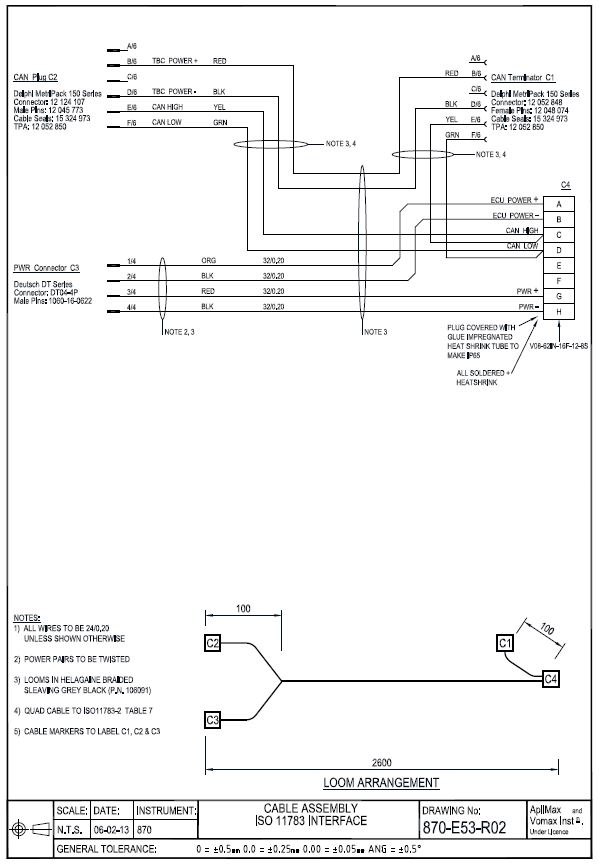

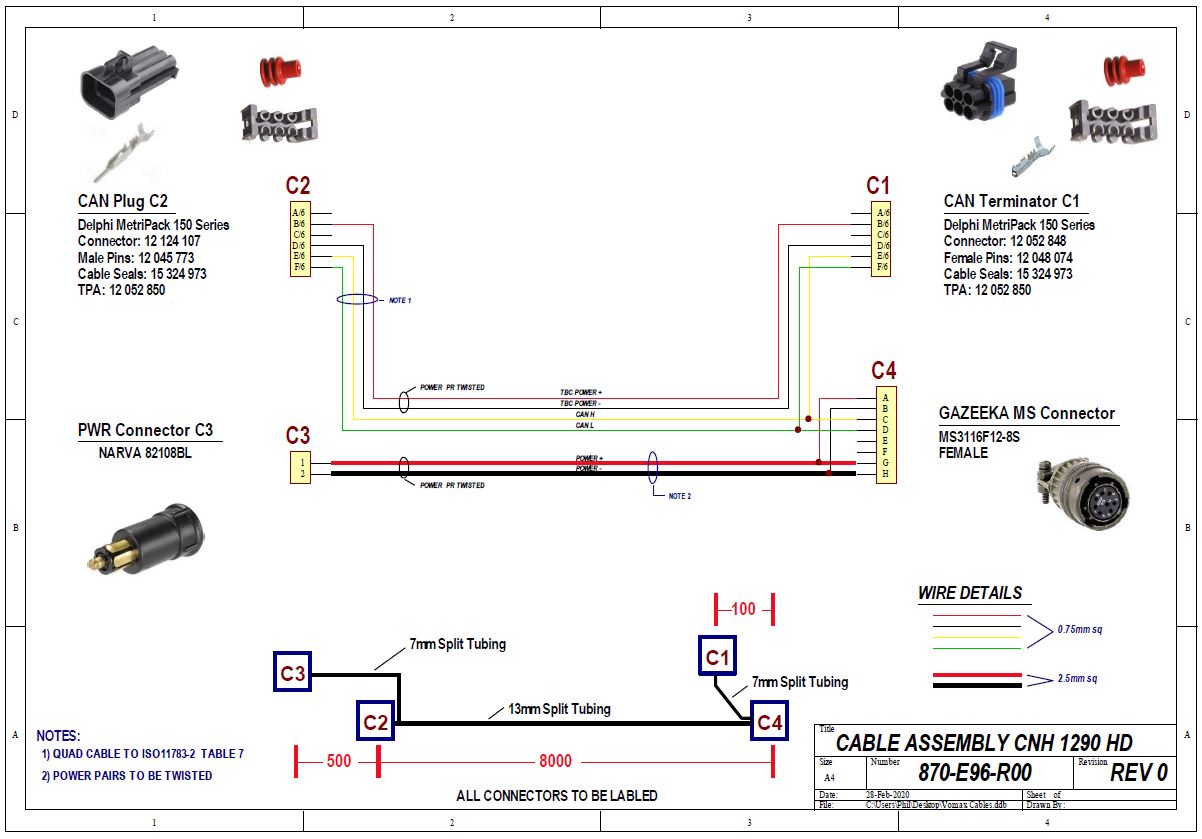

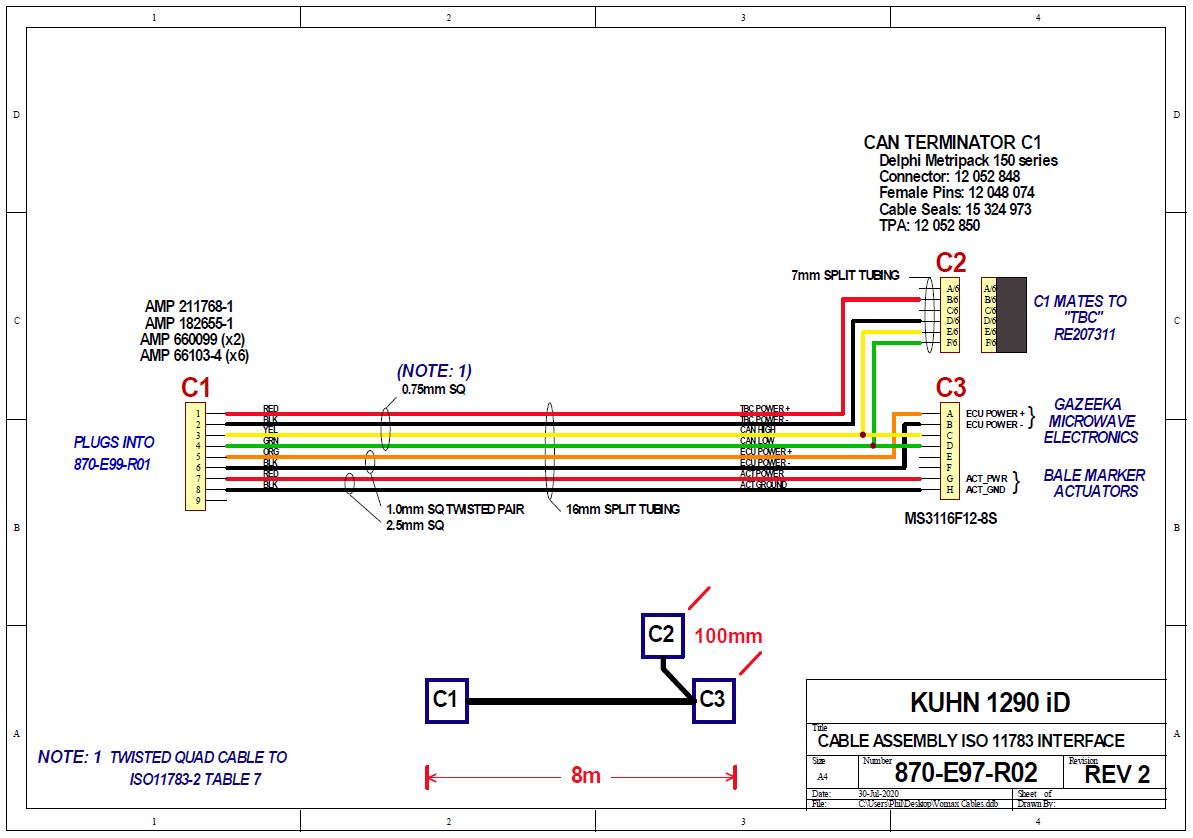

For the ISObus Gazeeka, this is the cable that connects the antenna with the electronics in it to the hay baler power and ISObus signals.

For the non-ISObus Gazeeka, this is the cable that connects the antenna with the electronics in it to the Gazeeka terminal in the tractor cabin.

This is the cable assembly that takes the microwave signal from the receiving antenna (typically on the right-hand side) back to the Microwave Module.

This is an electronic module which switches the power onto the marker units to mark the hay bale when required. These drivers have changed over the years. Originally an MC50 (up to serial #1304), then it was built into the Controller Modules (D1394 and D1400) then from #2501 on a separate module D1431-2.

The markers prior to serial number 2021 used solenoids to operate the aerosol cans. From serial no. 2021 on motor driven linear actuators were used. The two systems use the same voltage and current and can use the same drivers.

These are a metal cradle (steel originally, now aluminium) with the solenoid (or actuator) at the top to operate the aerosol marker can.

(CCM) this is a module that is installed in the passive antenna and is used to check the calibration of the instrument.

This is a measure of the Attenuation and the Delay when no hay bale is present. When a microwave reading is carried out with a hay bale present (Bale reading), the values of the Air Reading are subtracted from the Bale reading to obtain the changes in Attenuation and Delay caused by the presence of the hay bale only and nothing else.

These are values stored in the memory of the Gazeeka instrument, typically referred to as Items in the Menu structure of the human interface (VT or Gazeeka Terminal).

Parts Breakdown

Serial Number & Drawing Lookup

This PDF is essential for establishing the year of manufacture and the compatible components. It will also help to cross reference the wiring.

First you will need to get the serial number of the instrument. This is found inside the active antenna, located on a white sticker in the top left corner, on the wall of the antenna and will read in black writing S/N XXXX.

Once you have the serial number of the instrument, you can go to the contents of the PDF document and select the serial range it falls in and that will take you to the applicable drawing within the document.

This PDF is available to download from the documentation section on the Vomax website, once logged in.

S/N 801-2500: https://vomax.com.au/documentation/870-serial-number-drawings-lookup/.

S/N 2501-Present: https://vomax.com.au/documentation/870-serial-number-drawings-lookup/.

Error Messages

This is most likely caused by one of the following:

- A faulty baler cable or connector in the baler cable (connection between the universal terminal and the antenna) or,

- A faulty controller module in the antenna (typically, no LEDs flashing).

- Incorrectly wired internally (looking for RS422 signal not CAN).

- Not terminated correctly.

Troubleshooting Process

Power on the Gazeeka and take the lid off the active antenna (left-hand side).

- No LEDs flashing

- No power – cable needs to be repaired (see “Cable Configurations” section and repair notes below) or replaced

- Green LED flashing on microwave module and red LEDs flashing on control module

- Check that the 4pin Molex communications connector is plugged into CAN port (not RS422 port) – see below:

- Check that the baler cable has been correctly terminated (see installation guides for more detail) and ensure terminator isn’t faulty

- Installation guides can be found here https://vomax.com.au/documentation/document-type/technical/

- Faulty communications wire – cable needs to be repaired (see “Cable Configurations” section and repair notes below) or replaced

-

- Green LED flashing on the microwave module only

- Likely a failed control module – need to replace control module – see “Replacing Modules” section of this guide

Repair Notes:

If an electrical cable is suspected of being faulty, it needs to be tested before any other components are replaced. A shorted-out cable is capable of potentially destroying any replacement module, thus compounding the issue.

If you suspect a cable fault, use a new cable and lay it around the hay baler and connect it in at both ends (baler ISObus port and Gazeeka instrument at the rear of the baler). Power up and if this works OK, replace the faulty baler cable. If this does not power up and work OK, then commence replacing modules in the antenna still using the test cable until the system is OK. To determine which component is at fault.

Testing a cable with connectors at each end (“belling it out”)

The following assumes the connectors are labelled A, B, C …etc. The same applies to any other labelling of a connector such as 1, 2, 3 … etc.

Testing a multi-core cable with connector on each end by testing between pins “A” on one end to pin “A” on the other end, then B, C etc. tests the continuity of the cores, but it does NOT test if any of the cores are shorted out.

To tests if cores are shorted out one needs to test between pin A on one end then B, C, D etc. (all other pins) on the other end to make sure there is NO continuity, then between pin B on the same end and pins C, D, E etc. then pin C on the same end and pins D, E, F etc. until all pins are tested against all other pins for isolation.

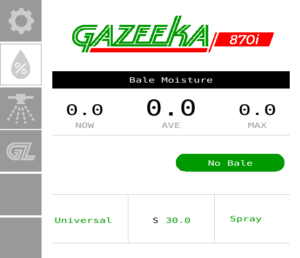

There is a good chance this is caused by a poor air reading (potentially part of a bale or another form of obstruction was apparent during the air calibration).

Conduct a new air calibration, making sure there is nothing in between the two antennae and they have a clear line of sight of each other. It is best practice that there is no hay within 2ft of the antenna beam.

If this does not fix the issue, a factory reset may be required.

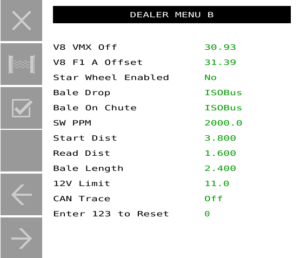

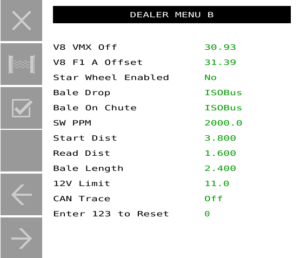

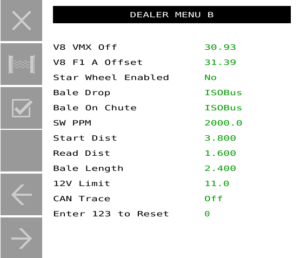

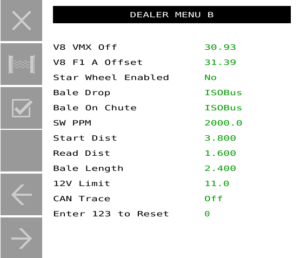

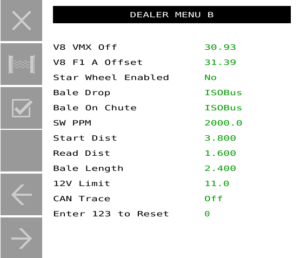

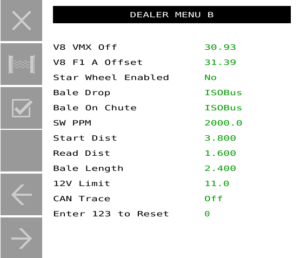

Enter the Dealer Menu

- From main screen (Analyse Mode)

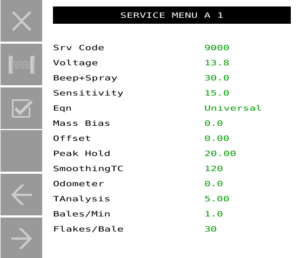

- Settings > Service Menu A 1 > 8000 > 8001

- Dealer Menu B > Enter 123 to Reset > 123

- Screen will reload. Shut terminal down and then reboot

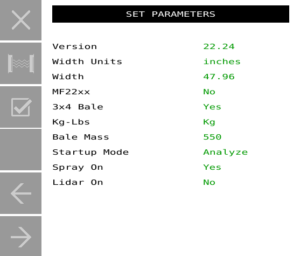

- Treat instrument as new. Go to Set Parameters and edit accordingly

- Conduct a new air calibration

Note: very dry hay (less than 8%), the microwave signal will be close to the air reading signal strength. So, an occasional “No Bale” when a bale is present may occur. This just means that the hay has a very low moisture content.

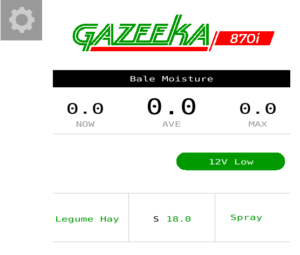

As the error code suggests, the Gazeeka system isn’t getting enough power. It is best to start at the source and work your way forward.

Troubleshooting Process

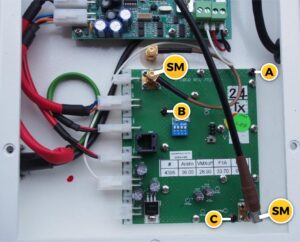

Using a multimeter, check the power is ok coming into the Gazeeka. This is done by measuring across the two-pin Molex connector (power in) on the microwave module (highlighted below). This should be >12v when the tractor is running (be careful not to short this out!).

If there isn’t 12v or more, there is likely an issue with baler cable (see the “No Connection” error code and “Cable Configurations” sections). However, if this looks ok, then there might be an issue with the chip that measures the voltage at the microwave module, this can be fixed as per below:

Changing 12v Limit

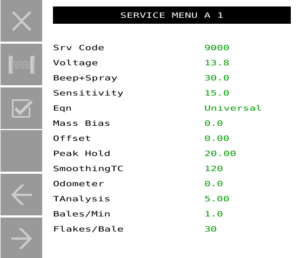

- Settings > Service Menu A 1 > 8000 > 8001

- Dealer Menu A > 12v Limit

- Change to 11.5 or 11 – depending on current value

If this doesn’t fix the issue, the microwave module will need to be replaced.

This generally means that the air reading values are higher than the max (attenuation > SAA Max).

Troubleshooting Process

First check for a loose or damaged microwave cable. This could be a kinked or crushed section of the loom. Following on from that, check the connection at either end to the antenna, this can be done by ensuring the connection is finger tight and if you gently wiggle and pull on the connection nothing comes loose.

It could also mean that a bale was still in the chamber or something obstructing the microwaves. Check that there is nothing in between the antennae, they have a clear line of sight and no hay within 2ft of faces. Conduct a new air reading.

If the above has not resolved the issue, proceed with the following steps.

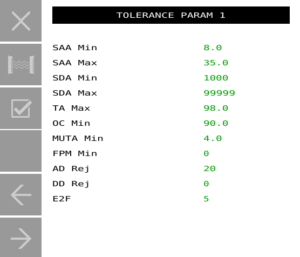

Check SAA Max

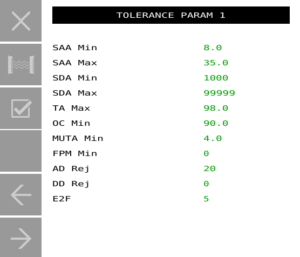

- Settings > Service Menu A 1 > 8000 > 9000 > Tolerance Param 1

- SAA Max (write this value down)

- Press the Test button

- What is the attenuation (it is the smaller number)?

If attenuation is slightly higher than the SAA Max (previously written down), then increase the SAA Max to just above the SAA measured through MW Mode.

Note: If the MW Mode attenuation reading (SAA) is less than 12 or greater than 60, this is a sure sign of a failed microwave board – this will need to be replaced. Typical readings are 18 – 23 (SAA) and 28,000 – 38,000 (SDA).

Note: the raw microwave data above (blue numbers) were taken from our test rig, these numbers will look different for a proper baler mounted instrument.

There are some model Gazeeka’s were the value of E2F needs to be increased from 500 to 9999. This spectral distortion limit was set very close to the operation limits, and in hindsight was far too low.

Changing E2F

- Settings > Service Menu A 1 > 8000 > 9000 > Tolerance Param 1

- E2F

- Change to 9999

Low Attenuation per Metre (Low APM) usually indicates that the hay is too dry to give a reasonable moisture reading (8% or less). In some instances it can also occur if the air calibration is not good enough, or the bale is very low density and or any combination of these.

Do a new air calibration following the steps below:

- Make sure instrument has been on for at least 2 minutes.

- Make sure the air path between the antennae is clear (i.e., no bale, chains, tailgate or anything else obstructing the microwave path).

- Ideally, the bale chamber should be completely empty of hay or at the very least the end of the bale should be inside the rear of the baler doors by at least 200mm/1′ – no bale within 600mm/2′ of the beam.

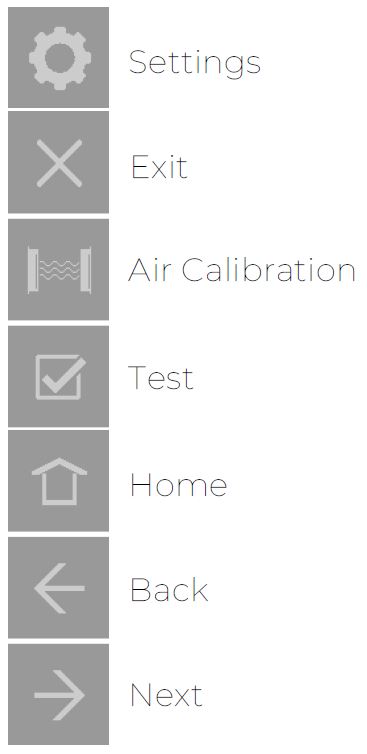

- From the Bale Moisture screen, press the COG key to enter the Moisture Settings Menu

- Press AIR key (microwave signal icon) to prepare Air Calibration sequence and then press it again to start

- Once status shows “Air reading complete” press X key to return to moisture analysis mode.

The “Reject” or “Distn” message is displayed when there are Spectral distortions in the microwave signal to such an extent that we have considered this may give erroneous moisture readings.

Geometric causes: This can be caused by a number of things. Sometimes this is caused by wet and dry “layers” of hay being next to each other or unusual size “lumps” of very wet hay or the leading or trailing end of a wet bale. Often you can get this spectral distortion effect by placing your body in front of the antenna. (It’s like “Ghosting” on a TV set – same spectral thing). Most times these distortions are determined by the physics and the geometry of the situation and the only resolution is to remove the cause of the distortion.

Component causes: It is also possible for an electronics fault in the microwave module to cause a spectral distortion. The microwave boards are tuned to remove internal distortion, however if the tuning screws have been tampered with (the holes in the back of the aluminum block) or a component has failed, this may cause the microwave spectrum to appear distorted and be rejected. (Like opening your cell phone and adjusting the tuning components in it). This would be rare, and we have never seen it in the field, only when first tuning new boards at the factory.

Changing rejection values: The two parameters concerned are ADrej and DDrej. (“DDrej” is typically zero by default). ADrej is typically set to 25. Sometimes changing this value to say 30 can fix or reduce the problem, but it should not be made any larger than this.

Removing the test: You can remove this spectral distortion test by setting both “ADrej” and “DDrej” to zero. (“DDrej” is typically zero by default). However, we do not like doing this, but if the end user believes that there are no anomalous readings being caused when this is done, then this could be a solution.

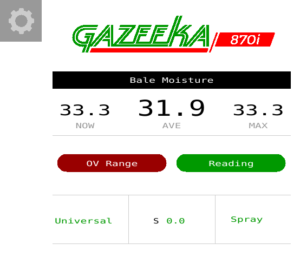

Note: If an “OV RANGE” or a “HI MOIST” situation occurs, then the cans should spray each time this is detected, but will not overwrite the alarm indication message with the word “spraying” as it would normally do.

However, if the “Beep and Spray” value is set to 00.0, then the cans will never spray, even if an “OV RANGE” or a “HI MOIST” situation occurs.

In Gazeeka units 2015 on, the control module does all the processing using the microwave data sent from the microwave module. If the wires between the two modules are not connected properly one gets the “No Comms” error. Make sure the plugs are in correctly and the wires pushed into the plugs. If the “No Comms” cable seems ok, in this scenario, it is likely that the microwave module has failed.

Troubleshooting Process

- Power up the Gazeeka and take the lid off the active antenna

- Look to see if the control module LEDs are flashing, if yes and microwave board LEDs are not – this would indicate a dead microwave board

- If the microwave module LEDs are flashing and the controller board LEDs are not, then it may be a failure in the controller board or the connecting 4 pin Molex may be damaged or loose (if not checked previously – as above)

- “No Comms” will also occur if a replacement microwave module is put in that does not have a compatible software version loaded on it (see the “Replacing Modules” section of this guide)

This could mean there is a corrupt parameter in the systems memory. Preform a factory reset, as per below.

Enter the Dealer Menu

- From main screen (Analyse Mode)

- Settings > Service Menu A 1 > 8000 > 8001

- Dealer Menu B > Enter 123 to Reset > 123

- Screen will reload. Shut terminal down and then reboot

- Treat instrument as new. Go to Set Parameters and edit accordingly

- Conduct a new air calibration

If you are using an optical sensor or a Lidar sensor input to the Gazeeka, then it could be a failed sensor or damaged sensor cable that is causing the “Wait” message. Disconnect the optical sensor/Lidar from the Gazeeka and see if this resolves the issue.

Whenever the system is running, a periodic test is done on the non-volatile memory. It stores parameters which will not be lost when the instrument is switched off. If this memory fails (and it does have a finite life) then the instrument may not calculate the microwave signal or the moisture value correctly. The only solution to this is to replace the microwave module.

Note that we do not test all of the memory locations (we would lose the operating program), so it is possible to have a memory failure without the “Memory Failure” message coming up.

OV Range (Over Range) means the microwave signal that is being measured is weaker than the limits we have set internally.

Assuming the person is not trying to measure very high moisture hay (e.g. balage) and there is no physical damage to the antennae, this could be caused by a broken microwave cable or a faulty microwave module.

Initially check the microwave cable for any obvious damage. This could be a kinked or crushed section of the loom. Following on from that, check the connection at either end to the antenna, this can be done by ensuring the connection is finger tight and if you gently wiggle and pull on the connection nothing comes loose.

Unlikely, but a memory corruption could cause this, so a system reset is a simple first step.

Enter the Dealer Menu

- From main screen (Analyse Mode)

- Settings > Service Menu A 1 > 8000 > 8001

- Dealer Menu B > Enter 123 to Reset > 123

- Screen will reload. Shut terminal down and then reboot

- Treat instrument as new. Go to Set Parameters and edit accordingly

- Conduct a new air calibration

If the air reading is OK, disconnect the microwave cable in the right-hand antenna and let it hang loose. There will be a weak signal still getting through just like a very high moisture bale. If an error message comes up (like a phase error) or a moisture reading above 26%, then the microwave system is reading well at both ends of the scale. Reconnect the microwave cable.

If the microwave module needs replacing refer to the “Replacing Modules” section of this guide.

Marker Units

All Gazeeka marking systems serial number 2501 on use a different electronic driver circuit board (D1431-2) which drives the markers separately. There are three LEDs which light up on this module when the marking system is operated. D4 (next to 870-E80 bridging loom between the control board and marker driver module) lights up red when the marking system is operated, this determines that communications between the two boards is ok. D5 (green LED under left hand side marker terminals) determines if the left side is working or not and D6 (green LED under right had side marker terminals) determines the right.

A lot of the time the system not marking comes down to the can. Make sure you clean any loose matter out from under the cap, put felt washer supplied under cap and then check that the spray can is easily sprayed by hand. If the can is not easily sprayed by hand, the actuator will struggle to fire the paint.

If the above seems ok, but the cans are still not working, continue onto the next section.

Initial checks:

- If this is a G-Link model (2023 or newer) make sure that the power for the markers is correctly connected in the tractor cab. On the baler loom, there is a connector junction with 3 leads. One is the round connector that plugs into the bottom of the Gazeeka terminal, the other 2 pin connectors are labelled terminal power and tractor power. Plug the lead coming out of the terminal into the terminal power 2 pin connector and then plug the power from the tractor into the tractor power connector.

- Inside the active antenna (left-hand side), make sure that the marker units are connected correctly and that all the other connections are correctly seated. If an issue is found here, rectify the issued and than use the toggle button on the control board to test markers again (SW1 – circled in red below).

If the above seems ok, there is likely to be a power issue or a failed marker driver module. Press the toggle button SW1 (circled red below – this is at the bottom of the board on newer models) on the control module and check that the D4 LED lights up red. This is the LED next to the communications loom that jumps between each board (870-E80), if this lights up, then the two boards are communicating with each other. Now press the toggle button and check that the D5 & D6 LEDs on the marker driver module light up green. If D4 lights up, but neither D5 & D6 light up, check that there is adequate voltage being supplied to the marker driver module. Grab a mulimeter and measure the voltage at the power in terminal (circled green below). If there isn’t 12v here, then there is an issue with the supply of power. Trace the internal loom and then baler loom (antenna to terminal) to find the issue. See the “Cable Configurations” section for baler loom wiring diagrams.

If the voltage is ok at the power in terminal for the marker driver module and the markers still don’t work, test each marker by putting a 12v supply straight to it and seeing whether it actuates or not. Disconnect the red and black wires from the marker control board (circled yellow below) for the actuator you wish to test and connect 12v supply correctly orientated. If they don’t plunge, then the actuator has failed and needs replacing.

If all of the above seems ok, then there is a high chance that the marker driver module has failed. Replace module (D14312-B).

Conduct above check to ensure that LEDs come on, for both the left and right-side markers. If this is the case and still only one can is marking, check the can operates manually as per above. If can seems ok, it is likely the actuator has failed – replace failed actuator.

The D1431-2 Driver drives each marker separately. Therefore, one can swap the two pairs of black and red wires over to see if the problem follows the wiring. If the other marker fails, then it is the electronics at fault. If the same marker fails, then the problem is with that maker unit.

Moisture Readings

CHECK LIST

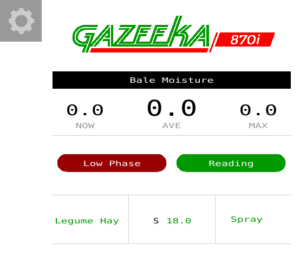

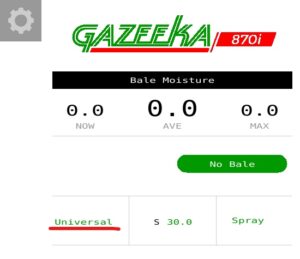

- Make sure they have chosen the correct equation (crop type) on the main Gazeeka screen.

- Check Set Parameters

- F1 > MENU

- Now use the ITEM button to check all the parameters are correct in this menu.

If OK, enter the Dealer Menu

- From main screen

- F1 > MENU > Service Menu A > 8001.

- Now check the air reading values

- Use the ITEM key to find SDA (this should be around 18,000 to 30,000).

- Use the ITEM key to find SAA (this should be around 18 to 26).

- If SAA is say around 40 or more, then the chances are the air reading was done with a bale (or something else) either in the beam or partially in the beam. Clear the air path (no bale or anything else within 3 feet of the antenna beam) and do a new air reading. If the air reading is still wrong, replace the microwave module with the correct version replacement.

For new users it is sometimes difficult for them to come to grips with the fact that we are calibrated to “oven dried moisture” which is the industry laboratory standard and not some arbitrary conductivity readings from a conductivity meter whose manufacturers may not say what it is calibrated against.

If “Version A” above does not fix the issue. There may be a requirement to do a factory reset – this resets the instrument back to the correct parameters it left the factory with and can potentially clear any corrupt parameters.

Factory Reset

- Enter the Dealer Menu

- From main screen (Analyse Mode)

- Settings > Service Menu A 1 > 8000 > 8001

- Dealer Menu B > Enter 123 to Reset > 123

- Screen will reload. Shut terminal down and then reboot

- Treat instrument as new. Go to Set Parameters and edit accordingly

- Conduct a new air calibration

- From main screen (Analyse Mode)

Microwave Check

From Gazeeka serial number 2699 on there is a Calibration Check Module (CCM) mounted in the passive antenna. A description on how to use this is in the owner’s manual, but is repeated below for reference.

If the instrument is measuring the full dynamic range, it is highly unlikely there is anything wrong with the microwave measuring system.

In-built calibration check (V19p83 on)

Your Gazeeka instrument has a Calibration Check Module “CCM” in the passive antenna (the one without the electronics in it on the right-hand side of the hay baler).

The combination of doing a normal air reading and then a CCM check will check that the microwave module is reading the microwaves correctly at both the very dry hay region and the very wet hay region.

A. Dry end: The air reading checks that the strongest signals which are present without a hay bale being present are being read correctly.

B. Wet end: The CCM reading checks that the weakest signals which are present with a very wet hay bale being present are being read correctly. This is done by inserting the CCM into the circuit with no hay bale between the antennae and doing the test.

A. Do an air reading (with the tractor running)

B. Do a Calibration check reading as follows (with the tractor running):

- Make sure the instrument has been on for at least 2 minutes.

- You may wish to remove the marker cans now as this test may sent them going.

- Take the cover off of the passive antenna (the one without the electronics in it on the right-hand side of the hay baler).

- Unscrew the microwave cable from the central antenna connector.

- Unscrew the microwave cable on the CCM and screw it onto the central antenna connector.

- Screw the microwave cable coming from the other antenna on the end of the Calibration check module. (See photo below).

- Make sure the air path between the antennae is clear (i.e. no bale or anything else). The end of the bale should be inside the rear end of the baler doors by at least 3ft.

- Settings > Press Test once (this will display the raw microwave data) > Then press test three times in quick succession

- If no error message is displayed, then the following message should come on the screen, where xx.x is approximately 20% moisture (+/- 1%): “xx.x% PASS (20.1% PASS – as shown above)

- If the test failed to pass, then the following message should come on the screen, where xx.x is the calculated moisture: “xx.x% FAIL

- Disconnect the CCM and screw back on the microwave cable coming from the other antenna

- Screw the antenna cover back on

- If you removed the marker cans, put them back now and return to Analyse Mode.

Replacing Modules

Microwave module 7p2 with controller code – Only some second-hand refurbished modules are now left.

Microwave module 7p2 no controller code – Slow interface.

Microwave module 7p2 no controller code, fast interface – Was required for full spectrum analysis.

Microwave module 8p0 – Form fit and function compatible with 7p2 and 9p0, but different gain values.

Microwave module 9p0 – Form fit and function compatible with 7p2 and 8p0, but different gain values.

Controller module D1394 – Replaced by controller module D1445 plus D1431-2 marker driver.

Controller module D1400 – Replaced by controller module D1445 plus D1431-2 marker driver.

Controller module D1431-1 – Replaced by controller module D1445 plus D1431-2 marker driver.

Solenoid driver MC50 – replaced by D1431-2.

Notes:

- All of the 7p2 microwave modules can be reprogrammed in the factory to be compatible with Gazeeka 870 units up to and including 2022 models.

- The fast interface was introduced in August 2014: 7p2 version 1p06, D1394 V14p30 (wiring: 870-E40).

- The 9p0 module was designed when some electronic chips used in the 8p0 module were no longer available during the Covid-19 pandemic.

- If you are using the D1445 plus D1431-2 to upgrade older system, then care must be taken to make sure the microwave module used has the fast interface.

Serial numbers Prior to 1305 and microwave module only units and can only be repaired by replacing the 7p2 microwave module with a re-furbished module loaded with software version 14.35. Or a complete factory upgrade.

Serial number 1305 to 1540 (E57) are “hybrid units” which only use the D1394 to drive the markers. The operating code is still in the microwave module. Repairs could be as follows:

- Marker driver failure, replace with a new or refurbished D1394 if one is available (note the link position is different to the shipped position). If not, then full system option below.

- Microwave module failure, replacing the 7p2 microwave module with a re-furbished 7p2 module if one is available loaded with software version 14.35. If not, then Full system option below.

- Full system option 1. If the modules are available, Replace the D1394 with one with the latest code for that module AND replace the microwave module with a refurbished microwave module 7p2 (fast interface). If not, then full system option 2 below

- Full system option 2. Replace the D1394 with the latest D1445 and D1431-2 with the latest code and replace the microwave module with a new of refurbished microwave module 7p2 (fast interface), 8p0 or 9p0.

Serial number 1541 to 2070 (E59/E40) are not compatible with 8p0 or 9p0 microwave modules. Repairs could be as follows:

- Marker driver failure, replace with a new or refurbished D1394 if one is available. If not, then full system option below.

- Microwave module failure, replacing the 7p2 microwave module with a re-furbished 7p2 module if one is available loaded with software version 1p11. If not, then full system option below.

- Full system option 1. If the modules are available, replace the D1394 with one with the latest code for that module and replace the microwave module with a refurbished microwave module 7p2 (fast interface). If not, then full system option 2 below

- Full system option 2. Replace the D1394 with the latest D1445 and D1431-2 with the latest code and replace the microwave module with a new or refurbished microwave module 7p2 (fast interface), 8p0 or 9p0.

Note: Any upgrade from a D1394 or prior (pre serial number 2071) to a D1445 and D1431-2 will require a new internal mounting bracket for the extra PCB support standoffs. The required part number is D1394-D1445. This includes a new control board (D1445), marker module (D14312), mounting plate (M118) and internal power loom.

Serial number 2071 on (year 2017)

| Serial Number | Microwave module | V8 Replacement requirements | V9 Replacement requirements |

| 2071 to 2500 (E74/E75 USA) (E40/E59 UA) | V7p2 V1p11 | Replace existing control module with a D1431-1 (or D1445 V22p00 and D1431-2) with at least V19.89 software | Replace existing control module with a D1431-1 (or D1445 V22p00 and D1431-2) with at least V19.89 software |

| 2501 to 3370 (E81/E82) | V7p2 1p11 | Upgrade software to at least V19.89 on the controller module | Upgrade software to at least V19.89 on the controller module |

| 3371 to current | V8 | Compatible | Compatible |

| Mid 2022 | V9 | Compatible | Compatible |

Please note that over the years a number of Gazeeka 870 instruments have been updated / upgraded (particularly in the USA) and the factory has no record of which serial numbers have been changed. It is often good practice to take a photograph of the electronics in the Active Antenna (with any version number that can be seen on a round green sticker) and send it to your ISF contact (in the USA) or sales@vomax.com.au with a clear description of the problem, brand and model of baler, and your contact details.

| SKU | Description |

| VMX850V7p2-R-V1p11 | Refurbished Microwave Module V7p2 with V1p11 (MW only) |

| VMX850V7p2-R-V14p35 | Refurbished Microwave Module V7p2 with V14p35 (with control code) |

CHECK THE MODULE COMPATIBILITY SECTION BEFORE CONTINUING.

Equipment List

- #2 pozi drive (or Phillips head) screw driver.

- 8mm open spanner (5/16″ wrench) for SMA connectors (or fingers OK).

Procedure

- Make sure the power is off.

- Using the 8mm wrench (or fingers) undo the SMA connectors (two) on the microwave board.

- Unplug the white “Molex” connectors on the edge of the microwave board assembly, noting which ones go where. (Note, the single white wire in the 4-way connector is only present in some older version modules).

- Using a pozi drive (or Phillips head) screw driver remove screws marked A, B & C in the picture (which are typically painted black). The microwave module will then be free to be removed.

- To reassemble, reverse this procedure. If you are not sure which Molex connectors go where, the diagram to show which Molex connectors go where is in the operator’s manual. The SMA connectors should be tightened to no more than 1Nm torque. If you do not have a torque wrench, tighten as firmly as you can using your fingers (they won’t come loose). Don’t use any other mechanical means.

- Replacement complete. If this is an upgrade, follow the upgrade procedure. If not, then power up and enter any parameters that need to be entered, then do an AIR Calibration. (see the manual for the commissioning procedure).

CHECK THE MODULE COMPATIBILITY SECTION BEFORE CONTINUING.

Equipment List

- #2 pozi drive (or Phillips head) screw driver.

- 8mm open spanner (5/16″ wrench) for SMA connectors (or fingers is OK).

Procedure

- Disconnect all the plugs on the board noting where each one goes.

- Unscrew the M3 screws which secure the board in place.

- Screw in the new board and replace the plugs.

- Task complete.

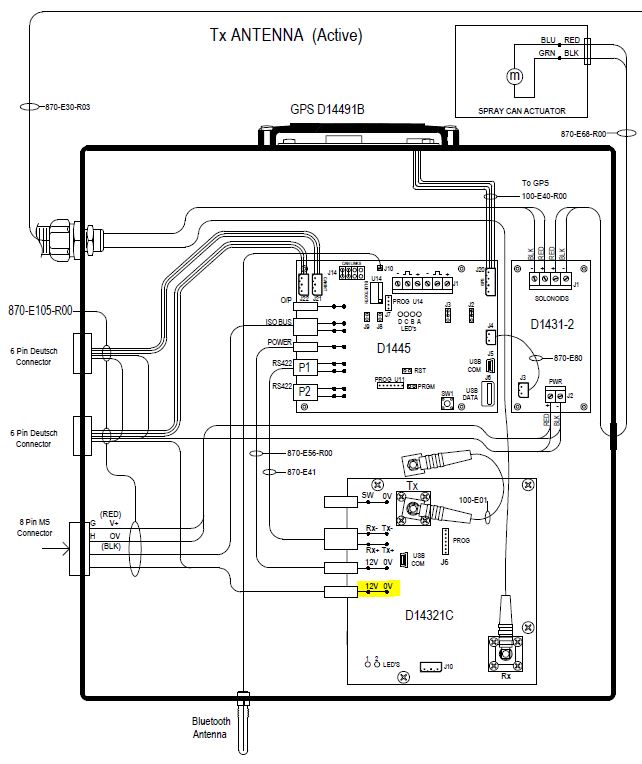

Note the only internal difference between a standard 870s Gazeeka using a Gazeeka terminal and an 870i ISObus unit is the position of the 4-way connector which goes to the external cable connection (see below). Note that there are also external cable differences.

Module LED Meanings

V7p2 / V8p0 Microwave printed circuit Module

Firmware versions 1.xx to 2.xx (most recent)

LED H501: Blinks when powered on and operating normally

LED H502: Blinks whilst reading microwaves

Note: 1.06 was first to use high speed Baud rate to the Controller Module.

Versions 1.00 to 1.05 are not compatible with current spare Controller Modules.

Firmware versions 9.xx to 15.xx (older versions)

LED H501: blinks whilst reading microwaves

LED H502: Not Used

D1394 / D1400 Controller Modules

LED A: 1Hz flash all the time. If continuously ON or OFF then the code is not operating correctly.

LED B: Flashes when an ISObus data packet is transmitted. If 20 or more packets are sent per second, then this may appear fully on.

If no ISObus connections is available, this LED will continue flashing looking to see if a new ISObus connection is trying to be made.

LED C: Flashes when there is communication with the microwave module.

LED D: Flashes when bale marking is enabled.

D1431 / D1445 Controller Modules

LED A Flashes with each RS422 transmission. Goes off once an ISObus link is established.

LED B Flashes with ISObus communicating (off until the link is established).

LED C flashes with each transmission received from the microwave module.

LED D Flashes on bale marking. (If this does not flash when the marker push button on the D1431-1 is pressed, then this will indicate dead code.)

LED ABCD All flash in sequence whilst new code is being loaded. (Via Bluetooth connection or USB memory stick).

Thus, if there are no connections (no RS422, ISObus or microwave module) only LED A will flash trying to communicate. This sequence is typically 3 flashes and then blank.

Updating Software & Bluetooth

Gazeeka Model 870 units from serial number 2501 on which have the D1431-1 or D14451-A controller printed circuit modules have a Bluetooth connection option.

The Bluetooth antenna is at the bottom of the active antenna (the one with the electronics in it). The antenna is connected via an SMA connector. To prevent damage, this antenna may be packaged separately and a rubber dust cap fitted to the SMA connector. To operate the Bluetooth connection the antenna is required to be attached.

We recommend that the cover of the antenna be removed during these operations so that the diagnostic LEDs can be viewed. This is especially true if updating software because if the link is disconnected during the uploading of new code, there is a good chance that only returning the antenna to the factory can resurrect the code.

Each of these instruments will have been loaded with a unique Bluetooth name which includes the instrument’s serial number, see also page 3 of operator manual. If the instrument has been factory reset in the field, the Bluetooth name may have reverted to a default “RN” number.

This Bluetooth connection can be used for the following:

- Operate the Gazeeka 870 from a device such as a Smartphone

- Allow remote access over the internet for servicing

- Allow remote software upgrades over the internet

The Gazeeka Model 870 can be operated via the Bluetooth connection for servicing.

This can be done as follows:

- Download and install the app – “Model 870 Remote Control”

- Android: In Settings on phone scan for Bluetooth devices and pair with phone. The Gazeeka Bluetooth name should be “Model870-18-Serial_Number of Device” (if the instrument has been factory reset in the field, the Bluetooth name may have reverted to an “RN” number).

- Once paired with the instrument, open the app. In the top right hand corner touch the three dots and select “Connect to 870”. Now control access via Smartphone is active.

- iPhone, open remote control app, in the top right hand corner touch the three horizontal stripes and select “Connect to 870”. Scan of Bluetooth Devices will find “Model870-18-Serial_Number of Device” (if the instrument has been factory reset in the field, the Bluetooth name may have reverted to an “RN” number). Select this and now control access via iPhone is active.

The Gazeeka Model 870 can be remotely operated via the Bluetooth connection and a Smartphone connected to the internet.

This can be done as follows:

- Turn your mobile data on so to access the internet or use a WIFI network (if within access range).

- Download and install the app – “Model 870 Remote Control”.

- In Settings on the phone scan for Bluetooth devices and pair the Gazeeka with the phone. Bluetooth name “Model870-18-Serial_Number of Device” (if the instrument has been factory reset in the field, the Bluetooth name may have reverted to an “RN” number).

- Once paired with the instrument, open the app. In the top right hand corner touch the three dots and select “Connect to 870”. Now control access via Smartphone is active.

- Now touch again three dots/dashes in right hand corner of your mobile devices Gazeeka app, and select “Enable Remote access”. Now Remote access from a Gazeeka website will be active.

Only proceed with a software update on a Model 870 unit if advised to do so from Vomax Instrumentation. Downloading the wrong software to a control module will brick the module and thus require replacement at your expense.

The Gazeeka Model 870 can be remotely software upgraded via the Bluetooth connection and a Smartphone connected to the internet.

This can be done as follows:

- Turn your mobile data on so to access the internet or if within access range to connect to a WIFI network.

- Download and install app – “Model 870 Remote Control”.

- Android, go to Settings on phone scan for Bluetooth devices and pair with phone. The Gazeeka Bluetooth name should be “Model870-18-Serial_Number of Device” (if the instrument has been factory reset in the field, the Bluetooth name may have reverted to an “RN” number).

- Once paired with the instrument, open the app. In the top right hand corner touch the three dots and select “Connect to 870”. Now control access via Smartphone is active.

- iPhone, open remote control app, in the top right hand corner touch the three horizontal stripes and select “Connect to 870”. Scan of Bluetooth devices will find “Model870-18- Serial_Number of Device” (if the instrument has been factory reset in the field, the Bluetooth name may have reverted to an “RN” number). Select this and now control access via iPhone is active

Select “Check for Updates” from the dropdown menu connect panel located at top right corner of the app. Enter the units’ serial number (found in the front of the Owner’s Manual or top left corner inside the active antenna – left hand side). Note: Mobile data or active WIFI network is required for this process.

- Enter password (*ask your authorised technician*).

- Install update version and reboot Gazeeka 870 Instrument.

- Reconnect to Gazeeka via the APP and check again for updates. There should be none.

- You are now required to do a factory reset.Enter the Dealer Menu

- From main screen (Analyse Mode)

- Settings > Service Menu A 1 > 8000 > 8001

- Dealer Menu B > Enter 123 to Reset > 123

- Screen will reload. Shut terminal down and then reboot

- Treat instrument as new. Go to Set Parameters and edit accordingly

- Conduct a new air calibration

- From main screen (Analyse Mode)

- The instrument now needs to be treated as new, requiring your applicable “Set Parameters” to be re-entered. Refer to the Commissioning / Setup section of the Owner’s Manual or your Quick Start Guide.

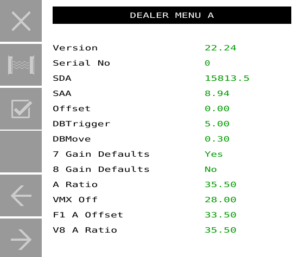

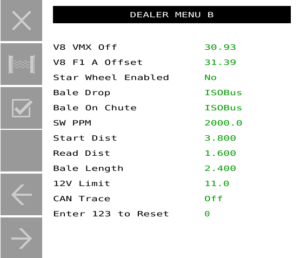

Dealer Menu Structure (Service Code 8001)

Please find steps below for accessing the Dealer Menu.

From main screen: Settings > Service Menu A 1 > 8000 > 8001

| Item | Options | Explanation | Range | Default Setting |

| Version | Current version of the software. | V24p00 | ||

| Serial No | Serial number of the instrument. | 0 to 9999 | 0000 | |

| System Delay Air (SDA) | Last air reading delay measurement. | R/O (pS) | 027,000.0 | |

| System Attn. Air (SAA) | Last air reading attenuation measurement. | R/O (dB) | 23.00 | |

| Offset | Adds any required bias to the moisture readings (leave at zero for best accuracy). | -99.99 to 99.99 | 00.00 | |

| DB Trigger | This value determines if a hay bale is present and triggers the start of the analysis process (uses half this value if low moisture levels are detected to increase bale detection sensitivity). | 0.0 to 99.9 | 05.00 | |

| DB Move | Change in attenuation to define bale movement (uses half this value if low moisture levels are detected to increase bale movement sensitivity). | 0.0 to 10.0 | 00.30 | |

| 7 Gain Def | Yes / No | Sets the gains to defaults on power up. | No | |

| 8 Gain Def | Yes / No | Sets the gains defaults on power up. | No | |

| 9 Gain Def | Yes / No | Sets the gains defaults on power up. | No | |

| 7 A Ratio * | T2/T1 ratio (module specific, internal value). | 00.0 to 40.0 | 35.30 | |

| 7 VMX Off * | Microwave module internal attenuation offset (module specific, internal value). | -99.90 to 99.99 | 28.00 | |

| 7 F1 A Off * | Value of the internal F1 attenuator used (module specific, internal value). | 0 to 40 | 33.50 | |

| 8 A Ratio * | T2/T1 ratio (module specific, internal value). Read from board. | 0 to 40.0 | R/O | |

| 8 VMX Off * | Microwave module internal attenuation offset (module specific, internal value). Read from board. | -99.90 to 99.99 | R/O | |

| 8 F1 A Off * | Value of the internal F1 attenuator used (module specific, internal value). Read from board. | 0 to 40 | R/O | |

| 9 A Ratio * | T2/T1 ratio (module specific, internal value). Read from board. | 0 to 40.0 | R/O | |

| 9 VMX Off * | Microwave module internal attenuation offset (module specific, internal value). Read from board. | -99.90 to 99.99 | R/O | |

| 9 F1 A Off * | Value of the internal F1 attenuator used (module specific, internal value). Read from board. | 0 to 40 | R/O | |

| Bale Drop | ISObus | This enables the Gazeeka to use the bale detected limit switch at the end of the bale chute to stop microwave reading of bale gaps and to determine the average and peak moisture per bale. | ISObus | |

| Bale on Chute | ISObus | If on power up the Krone ISObus is detected, make this “ISObus”. On an AGCO baler with or without ISObus this may be used with a bale on chute switch that we put in. | ISObus | |

| SWPPM | Number of pulses per metre of hay bale movement from the star wheel rotary encoder. | 0.0 to 9999.0 | 1000 | |

| 12V Limit | Lower limit for the measurement of microwaves (0.0 = don’t do test – set to 12). | 0.0 to 15.0 | 11.0 | |

| CAN Trace | On/Off | Records CAN messages for development. | Off | |

| Enter 123 to Reset | N/A | Resets all parameters to default values – AUTHORISED EMERGENCY USE ONLY | N/A |

* These values are written on the front of each microwave module. If the system is running a V8 or V9 ensure the values you see in the dealer menu match what is printed on the sticker on the microwave module (bottom board, left-hand side antenna).